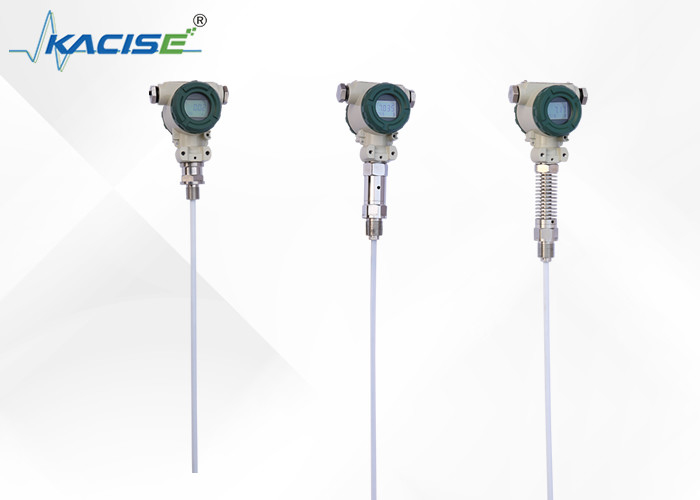

Product Description:

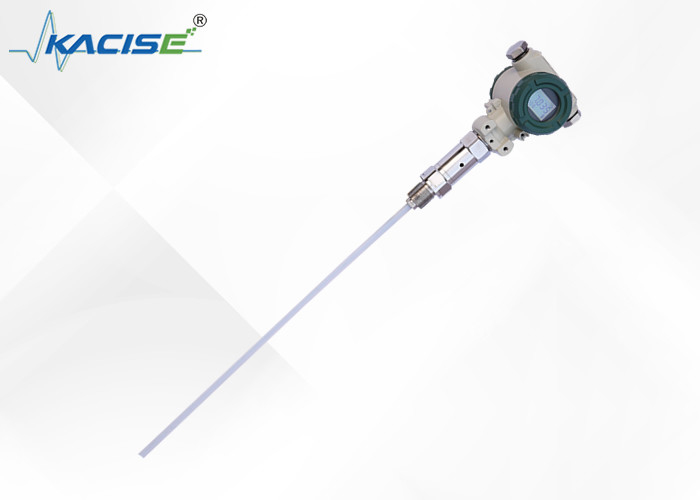

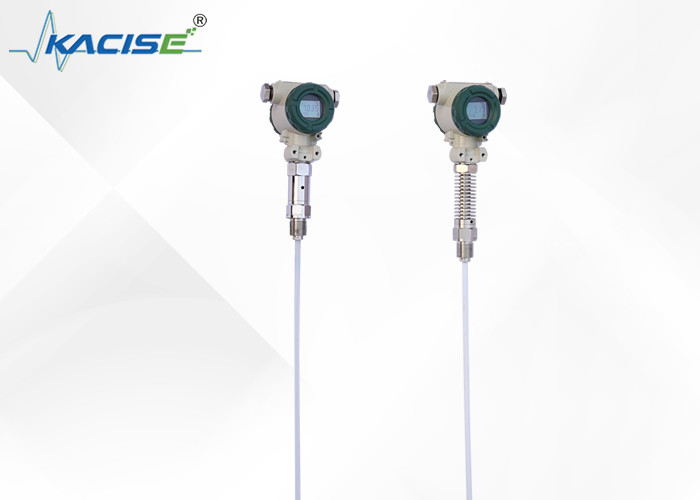

The KCF600 series capacitive level transmitter is designed for continuous detection of liquid in harsh conditions where there is high temperature and pressure, high corrosion, easy crystallization, and easy plugging. This device is ideal for measuring water, acid and alkali solutions, and the water level in the boiler. Unlike traditional level transmitters, there are no movable or flexible parts in the KCF600 series. It offers high reliability and precision, has a reasonable cost, and can replace float type, input type, and differential pressure type of level transmitter in various situations.

The key parts of KCF600 series capacitive level transmitter adopt an advanced RF capacitive sensing circuit. The temperature is precisely compensated, and linearity is corrected, which results in a standard electrical signal, usually 4~20 mA. The device has options for HART, CANBUS, and 485 communication protocols for system configuration. The full range of KCF600 series transmitters has a self-calibration feature where users can calibrate for "zero" and "range" by using two keys to adapt to the different requirements of a complex situation.

The KCF600 series capacitive level transmitter is designed with impact resistance and easy installation features. It is suitable for continuous detection of various corrosive liquid in high-temperature and high-pressure environments, or those prone to crystallization or plugging. This device can replace traditional level transmitters with no flexible or movable parts, offering high reliability and precision. Additionally, it has a reasonable cost, and users can get automatic calibration (both zero and range) with its self-calibration feature.

The KCF600 series capacitive level transmitter is an effective solution to the continuous detection of liquids in harsh conditions. It is suitable for measuring water, acid, and alkali solutions, and water levels in the boiler. Its advanced RF capacitive sensing circuit is precisely compensated and linearity corrected that results in a standard electrical signal. Users can opt for HART, CANBUS, and 485 communication protocols when configuring the system.

The KCF600 series capacitive level transmitter has no movable or flexible parts, which makes it different from traditional level transmitters. This device offers high precision and reliability, as well as a reasonable cost, and can replace other level transmitters in various situations. Its self-calibration feature, which users can execute automatically, allows it to adapt to complex situations effectively. With its impact resistance and easy installation features, the KCF600 series capacitive level transmitter is ideal for harsh environments with high temperature and pressure, high corrosion, easy crystallization, and easy plugging.

Features:

Simple and Reliable Structures

The device features simple structures, without any movable or elastic components. As such, it boasts high reliability and requires minimal maintenance. Even under normal circumstances, it's not necessary to perform regular medium and small repairs.

Diverse Signal Output for System Configurations

In order to facilitate different system configurations, this device offers a variety of signal output options to choose from.

Accurate Measuring in High Temperature and High Pressure Containers

This device is designed to work accurately in high temperature and high pressure containers, regardless of the measured liquid's temperature, specific gravity, and container shape, as well as the influence of pressure.

Ideal for Measuring Corrosive Liquids

The device is especially suitable for the measurement of corrosive liquids, such as acid and alkali solutions.

Overcurrent, Overvoltage, and Power Polarity Protection

This device is designed with perfect protection against overcurrent, overvoltage and power polarity issues.

Technical Parameters:

The detection range of this device is from 0.01 to 30 meters. It has two levels of accuracy, level 0.2, and level 0.5. The pressure range it can handle is -0.1MPa to 32MPa. The probe temperature can range between -50 ℃ and 250 ℃. For ambient temperatures, it can work within -20℃ to 60 ℃, while for storage, it can withstand temperatures from -55℃ to +125 ℃. The device can produce an output signal of 4-20mA, 4-20mA with HART communication, 485 or CAN bus communication. It requires a supply voltage of 12-28VDC and should be powered by the safety barrier. The device can be fixed using screw mounting M20×1.5, M27×2, or flange mounting DN25, DN40, DN50. The device can be customized to fit special specifications.

The wetted material used in this device includes 316 Stainless steel, 1Gr18Ni19Tior, or PTFE. It has a long-term stability of ≤0.2%FS/Year and a temperature drift of ≤0.02%FS/℃ (range of 0-70℃). The device has explosion levels of Intrinsically Safe ExiraⅡC T6 and Flameproof Ext II C T5. It has IP67 protection and Intrinsically Safe parameters, including Ui: 28VDC, Ii: 93mA, Pi: 0.65W, Ci: 0.042uf, and Li: 0mH.

Applications:

The Kacise Fluid Level Meter is highly accurate, with a range of ±2%, ±5%. It is equipped with capacitive sensors for point level detection, making it ideal for a wide range of applications. The capacitive water level sensor is perfect for measuring liquid levels in tanks, pipes, and other containers. The capacitive level switch is suitable for use in most industrial and commercial environments.

The Kacise Fluid Level Meter is designed to provide reliable and accurate measurements in harsh environments. It has an IP67 rating, which means it is protected against dust, water, and other contaminants. This makes it suitable for use in outdoor and indoor applications.

The Kacise Fluid Level Meter comes with a range of output signals, including 4~20mA, 4 ~ 20mA with HART Communication/485/CAN Bus Communication. This ensures compatibility with most control systems and makes it easy to integrate into existing installations.

The Kacise Fluid Level Meter has a wide operating temperature range, with a storage temperature of -55℃~+125 ℃. It is powered by a 2~28VDC power supply voltage and should be powered by the safety barrier to ensure safe operation.

The Kacise Fluid Level Meter is suitable for a wide range of applications, including but not limited to:

- Water and waste water treatment plants

- Chemical and petrochemical plants

- Pharmaceutical and biotech plants

- Food and beverage plants

- Power generation plants

- Oil and gas refineries

- Industrial and commercial buildings

Overall, the Kacise Fluid Level Meter is a reliable, accurate, and versatile product that is suitable for a wide range of applications. Its capacitive sensors for point level detection make it ideal for measuring liquid levels in tanks, pipes, and other containers. Its IP67 rating ensures reliable operation in harsh environments, and its range of output signals ensures compatibility with most control systems.

Installation and commissioning:

The cable and rod level transmitter has a variety of fixed ways to adapt to different site conditions. When the site cannot provide the process facilities such as the M20 × 1.5 female thread or flange, you can choose three methods of installation (wall-mounted, horizontal pipe rack and vertical tube rack, which make you handy in the on-site installation.(With pictures)

When measuring the media of the larger mobility, the user can choose the weight attachment in order to prevent the sensor form violent swing, which can play the role of the stability of the sensor. The heavy objects must be put into the bottom of the container when adding weight, so as not to break the sensor’s wire.

When the site conditions are bad, the user should use the sensor shield to protect the sensor in order to avoid foreign body damage or affect the measurement accuracy.

If the containers are not metal, we need to put the transmitter enclosure with a wire access to the bottom of the container when using a KCF600 rod level transmitter; otherwise the measurement is not accurate.

This product has been calibrated at the factory; he need for field adjustment may take the following methods:

A: Intelligent circuit debugging method:

Site-zero----- When the liquid level is located in the lowest place, holding down the "Z" key and "S" key for 8 seconds after the same time release, and then "Z" key click, the output current is automatically adjusted to 4mA.

Site - filled ------ When the liquid level at the highest place, holding down the "Z" key and "S" key for 8 seconds after the same time release, and then "S" key click ,the output current is automatically adjusted to 20mA.

B: Analog circuit debugging method:

When the liquid level in the next limit, use the screwdriver slowly rotating "Z" potentiometer, observe the ammeter readings close to 4mA

When the liquid level in the upper limit, use the screwdriver slowly rotating "S" potentiometer and observe the ammeter readings close to 20mA

And operate it for 2-3 times more, until the zero and span were accurate 4mA and 20mA. After adjustment, tighten the cover of the transmitter should be.

Note:

1. Products supply with product certification and manual, which have product number, technical parameters, wiring diagram, and the date of manufacture, please check to avoid the mistake.

2. The installation should be based on the product connection and thread types, check the site interface is consistent with the product interface or not. Tighten the threaded connection slowly, pay attention to sealing, the torque cannot be directly added to the transmitter housing and can only be added to the six-party transmitter interface.

3. Wiring should be strictly in accordance with company instructions.

4. This product is a precision Energy conversion instrument, prohibit disassemble, collision, fall and hard rejection to play.

5. Transmitter Work immediately after power on, but output could be stability after warming up for 30 minutes.

6. Abnormal use ,turns off the power, check, or contacts our technical department directly.

7. Transportation, storage should be to restore the original packaging and stored in a cool, dry, ventilated warehouse.

8. The installation process should pay attention to avoid the breaking of the skin of the sensor wire.

9. When installing the sensor wire, the distance from pool wall should be at least 10CM above, otherwise the measurement would be not accurate.

10. The grounding line of the whole PTFE structure and the rod level must be conduct with

measured media; otherwise the measurement would be not accurate.

11. The installation site should take effective lightning protection measures.

12. The enclosures of any transmitter in this series must be grounded; grounding resistance should be less than 4Ω.

13. Safety barrier should be made explosion-proof certification; its installation requirements should follow the requirements of instructions.

14. When the transmitter is used to "0" zone to the barrier-powered power transformers must meet the requirements of GB3836.4-2000 NO. 8.1.

Support and Services:

The Fluid Level Meter product technical support and services include:

- Assistance with installation and setup

- Troubleshooting issues and providing solutions

- Regular maintenance and calibration services

- Repair services for any damages or malfunctions

- Technical training and resources for customers and distributors

- Continuous product improvement updates and enhancements

Packing and Shipping:

Product Packaging:

The Fluid Level Meter comes in a sturdy cardboard box for protection during transportation. The product is securely packed with foam inserts to avoid any damage during shipping.

Shipping:

The Fluid Level Meter is shipped within 2-3 business days via standard shipping. The shipping cost is calculated based on the destination and weight of the package. Customers will receive a tracking number to monitor their shipment. Expedited shipping is also available at an additional cost.

আপনার বার্তাটি 20-3,000 টির মধ্যে হতে হবে!

আপনার বার্তাটি 20-3,000 টির মধ্যে হতে হবে! অনুগ্রহপূর্বক আপনার ইমেইল চেক করুন!

অনুগ্রহপূর্বক আপনার ইমেইল চেক করুন!  আপনার বার্তাটি 20-3,000 টির মধ্যে হতে হবে!

আপনার বার্তাটি 20-3,000 টির মধ্যে হতে হবে! অনুগ্রহপূর্বক আপনার ইমেইল চেক করুন!

অনুগ্রহপূর্বক আপনার ইমেইল চেক করুন!